| Subject | ARCH 119- Building services |

| Session | Tem I |

| Year | 2025-26 |

| Date | 22nd July, 2025 |

| Time | 11:30 a.m. onwards |

| Venue | Karanjade, Navi Mumbai |

| Faculty Co-ordinators | Prof. Neha Sayed |

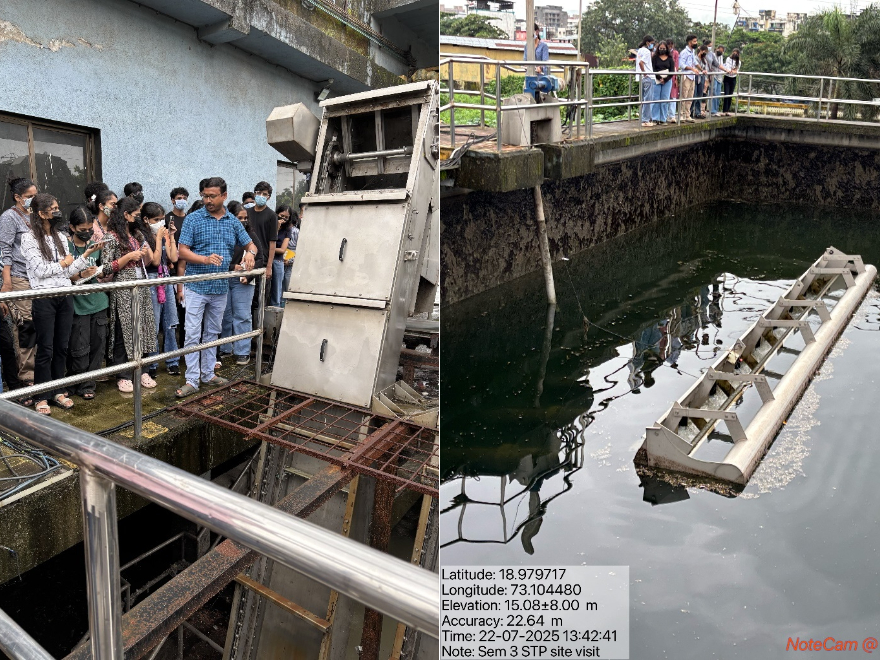

On 22nd July 2025, our second-year (4th semester) students visited the Sewage Treatment Plant (STP) at Karanjade, Navi Mumbai. A total of 60 students participated in the visit, which was led by Prof. Neha Sayed and accompanied by Prof. Jasmine Bhavsar, Prof. Snehal Ghag, and Prof. Shubham Tapkir. This visit organised under the Building Services subject, aimed to connect theoretical learning with practical field experience. The plant’s engineering team guided participants through each stage of treatment, with opportunities for interaction and note-taking.

The visit enhanced student’s understanding of sewage treatment systems and their crucial role in maintaining urban health and environmental quality. The plant is responsible for treating domestic wastewater through multiple stages.

Key insights included:

- The functional components of wastewater management in cities.

- The environmental benefits of treatment and reuse

- Adherence to quality and discharge regulations.

- The importance of integrating sustainable water infrastructure into urban planning and design.

The visit was guided by Executive engineer, Sewerage Project, CIDCO at Karanjade, Navi Mumbai.

The Karanjade STP is a municipal facility that treats domestic sewage collected from residential, commercial, and institutional areas of Navi Mumbai. The treated water is reused for non-potable applications or safely discharged into water bodies.

Points covered in site visit

1. Collection System: Underground pipelines transport sewage from multiple zones.

2. Treatment process:

i. Preliminary Treatment: Screening and grit removal to eliminate large solids and debris.

ii. Primary Treatment: Sedimentation tanks for sludge separation.

iii. Secondary Treatment: Biological treatment via the activated sludge process.

iv. Tertiary Treatment: Polishing and disinfection to meet safety standards.

3. Effluent Reuse: Treated water supplied for landscaping, flushing, and construction.

4. Sludge Management: Processed and disposed of as per regulatory guidelines.

5. Odour & Safety Measures: Systems in place for environmental control and worker safety.

The visit provided valuable exposure to the design, operation, and maintenance of sewage treatment facilities. Direct interaction with plant engineers deepened understanding of plant capacity, treatment efficiency, and operational challenges. The experience reinforced the importance of incorporating sustainable wastewater management solutions in architectural and urban planning practices.