| Subject | Architectural Building Construction & Materials 4 |

| Session | 2022-23 |

| Year | Third year |

| Course code | BARC603 |

| Credits | 03 |

| Semester | IV |

| Examination Scheme | Internal : 50 External : 00 Theory Paper : 50 Total Marks: 100 |

| Faculty | Subject coordinator : Prof. Rupali Vaidya |

| Faculty team |

|

Aim:

The site visits was conducted to have a practical and hands on experience of building construction methods and understanding of site dynamics.

Objectives:

- To observe on-going basement construction work on site

- To observe different components associated with precast concrete construction

- To understand the methods and techniques for precast construction

- Physical understanding of materials, transportation on site and assembly

- To learn method of manufacturing precast girders, precast slabs, beams and walls

- To understand advantages and disadvantages of Precast construction

About the Project Site:

Project Name: B. G. Shirke low cost housing project

Project Address: B. G. Shirke Const. Tech. Pvt. Ltd. Taloja, Navi Mumbai

Site Visit Date: 13th and 20th December, 2022

Faculty Team: Prof. Rupali Vaidya, Prof. Vrinda Padhye, Prof. Avinash Sabhagani, Prof. Tanaya Deka, Prof. Sayalee, Prof. Prashant

About the Site Visit:

B. G. Shirke Construction Technology Pvt. Ltd. is a plus Rs. 3,000 Crore Group with millions of sq. ft. of construction encompassing mass housing projects, administrative facilities, airports, bridges, roads, flyovers, monuments, entertainment malls and industrial complexes.

The Shirke Group is recognized as the largest constructor of mass housing projects with its proven industrialized ‘3-S’ Prefab Technology in India.

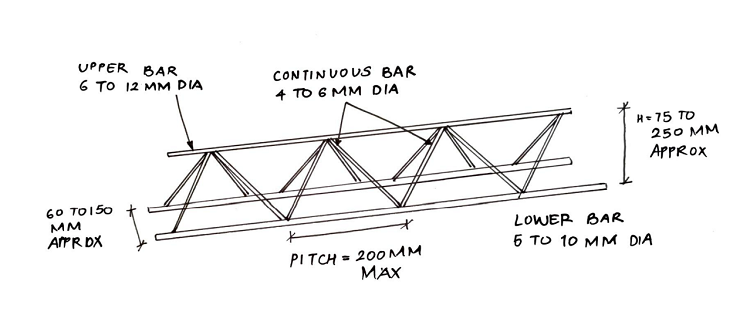

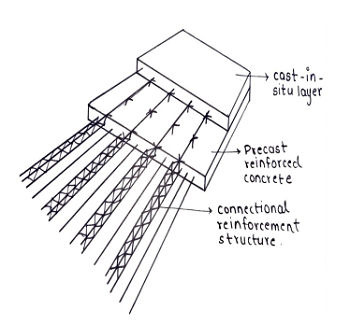

A technical site visit to precast manufacturing plant to understand the process of precast columns, beams, staircase, lintels, slabs & girders.

Site Observations:

- The whole precast plant is fully automated plant all work is done by heavy machineries minimum amount of labour.

- For each and every activity machines are used. i.e. For cutting of bars, for stirrups, for welding etc. For lifting of reinforcement and precast member there are heavy girders.

- The factory consists of batching plant, storage plant. They cast all the units separately i.e. there are separate place for slab, beams, columns etc.

- The whole unit is made sequentially by fully automated machines and it takes around 40 min to 45 min to complete one cycle.

- We had observed the casting process during the slab casting is in progress, the placing of reinforcement, its cover, its spacing, amount of concrete poured, its compaction etc. M30 grade of concrete is used for the entire unit with vary slumps.

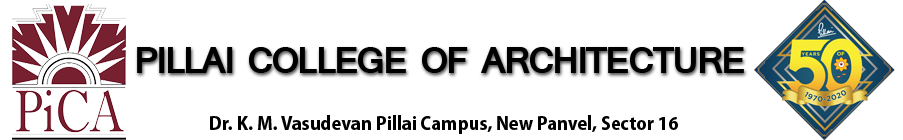

Methods of Manufacturing Lattice girder

Output of the Site Visit:

Output of the site was in the form of A3 size reports and sketches